Gelacell™ 3D Nanofibrous Scaffolds

Introduction

Gelacell™ is a non-woven, highly porous scaffold specially designed for in vitro 3D cell culture and tissue engineering. It has a unique nanofibrous structure that closely mimics the natural extracellular matrix. Gelacell™ offers exceptional biocompatibility and non-toxicity across a variety of cell types.

Gelacell™ is produced using patented halospinning technology that provides unprecedented 3D architecture with extensive surface area for cellular activities. Compatible with various cell lines and culture conditions.

Gelacell™ products

- Browse all Gelacell™ products

-

Browse by format:

- Scaffold sheets (tissue engineering/organoid scaffolds)

- Scaffold inserts for plate wells (short to medium term 3D cell culture)

- Scaffolds preloaded in plate wells (short to medium term 3D cell culture)

- Scaffolds on cell crowns in plates (long term 3D cell culture)

- HaloScreening plates (High-throughput screening [HTS])

-

Browse by material:

- Didn't see what you were looking for? Gelacell™ scaffolds can be produced in a wide variety of materials and configurations. Please contact us to discuss your specific needs!

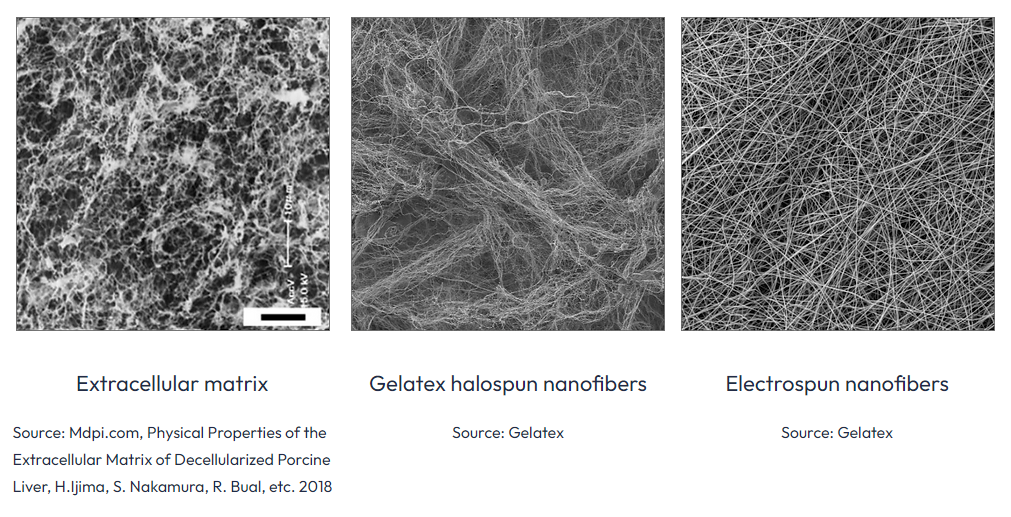

Morphological benefits of Halospun nanofibers

- High surface-to-volume ratio: Halospun nanofibers have an extremely high surface-to-volume ratio, which enhances cell attachment, growth, and differentiation.

- Biomimicry: Nanofibers, due to their scale and structure, can effectively mimic the extracellular matrix (ECM) of various tissues, providing a more natural environment for cells.

- Enhanced cell interactions: Due to their morphology, halospun nanofibers promote superior cell-to-cell and cell-to-fiber interactions, encouraging the formation of 3D cell networks.

- Porosity: The interconnected porous structure of these nanofibers facilitates efficient nutrient and oxygen transport to cells, which is critical for cell survival and proliferation.

- Customizability: Fiber diameter, alignment, and density can be controlled during the halospinning process, allowing for customization to suit specific cell types and applications.

- Flexibility in material selection: Halospun nanofibers can be made from a wide variety of polymers, both natural and synthetic, allowing for a range of mechanical and chemical properties to suit different cell culture needs.

The 3D structure created by halospinning closely mimics the natural extracellular matrix.

Gelacell™ 3D advantages vs conventional 2D systems

- Acts as an in-vitro extracellular matrix

- Preserves the natural cell structure

- Enhances cell-to-cell and cell-to-matrix interactions

- Supports optimal cell differentiation

- Porous structure facilitates nutrient diffusion

- Protects cells during laboratory practices

In traditional 2D in vitro systems, cells tend to flatten and stretch in a monolayer, creating stress and modifying their natural behavior.

3D in vitro scaffolds help to preserve the natural shape of the cells, reduce the stress conditions, and allow for the structural conformation found in native tissues. In a 3D system, cells retain more of their original functions, surface activity, and natural complex interactions.

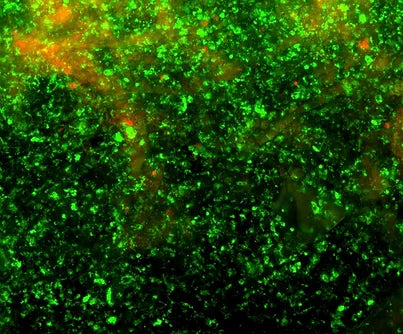

Promotes cell proliferation

Halospun nanofibrous scaffolds support cell-to-cell and cell-to-scaffold interactions, enhancing cell proliferation and cell differentiation. Besides already advantageous fibrous structure, incorporation of growth factors or antimicrobial agents is possible, as well as use of raw materials that support cell attachment.

BHK -21 Fibroblasts 7 – days proliferation on Gelacell™ chitosan scaffolds.

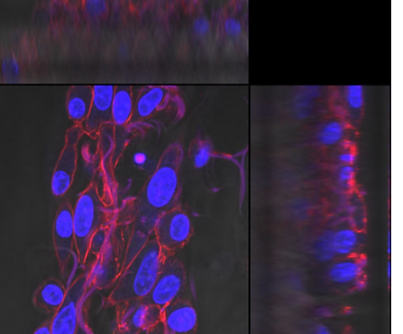

Advanced cell migration

During static seeding on a Gelatex nanofibrous scaffolds, cells migrate inwards in the scaffold. This phenomenon is unique to the halospun nanostructure and does not occur with electrospun nanofibers.

Confocal microscopy images of BHK-21 cells in static culture after 24 hours. Cell nuclei are visualized in blue, nanofibers in purple.

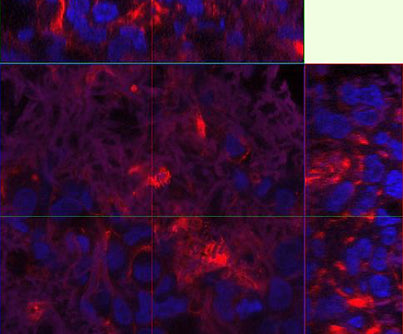

Uniform cell growth and tissue formation

Cells demonstrate uniform growth, creating formations that mimic in vivo tissue characteristics. Gelacell enables the precise construction of tissues, pushing the boundaries of in vitro research.

Confocal microscopy images of HepG2 cells (human liver cancer cells) cultured on Gelatex scaffold. Cell nuclei are visualized in blue, nanofibers in purple.

Example applications

- Cardiotoxicology: Aligned scaffolds improve both structural and functional read-outs in cardiomyocytes, growing 3D cultures of spontaneously beating hiPSC-derived cardiomyocytes (hiPSC-CMs) in well format. hiPSC-CMs grown on such aligned 3D plates showed statistically significantly higher Ca2+ transient rising slope (indicating faster kinetics), lower peak width durations, and lower amplitudes as compared to standard 2D tissue culture plates

- Toxicology studies: Hep G2 liver cancer cells are often used as model cultures for toxicology studies in-vitro. Nanofiber scaffolds have proven to provide a suitable environment for liver cells.

- Drug discovery in 3D tissue model: Cancer cells grown in more physiologically relevant 3D cultures have shown increased drug resistance compared to traditional 2D systems. Nanofiber scaffolds have been successfully used as a matrix for numerous cancer cell models in 3D drug screening: liver, breast, ovarian as well as lung cancer models.

- Stem cell research: Differentiation of neural stem cells into mature neurons within nanofiber scaffolds.

Gelacell™ is highly compatible with 3D cell culture studies

- Wide range of cell seeding density/well (10^4 to 10^6).

- Progressive growth of cells in the 3D environment.

- Compatible activity assays include (but are not limited to):

- MTT

- MTS

- CCK8

- Dyes compatible with the scaffold:

- Calcein AM/Propidium Iodide (Live/Dead)

- Phalloidin conjugates

- FDA

- DAPI/Hoechst

- Direct analysis of activity assays under well plate reader.

- Scaffold preserving natural cellular structure.

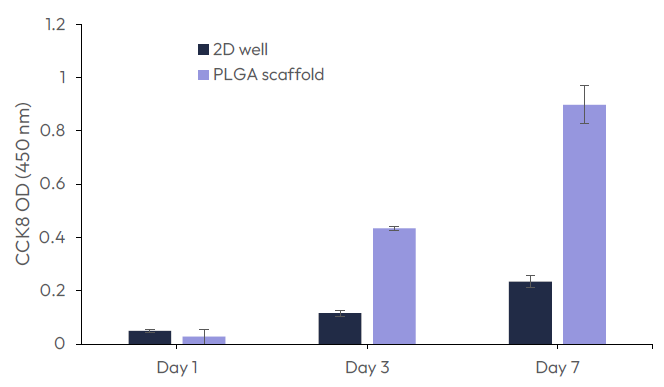

Growth of fibroblast (BHK21) on GelacellTM PLGA scaffolds in comparison with cells on the bottom of the well plate (2D well).

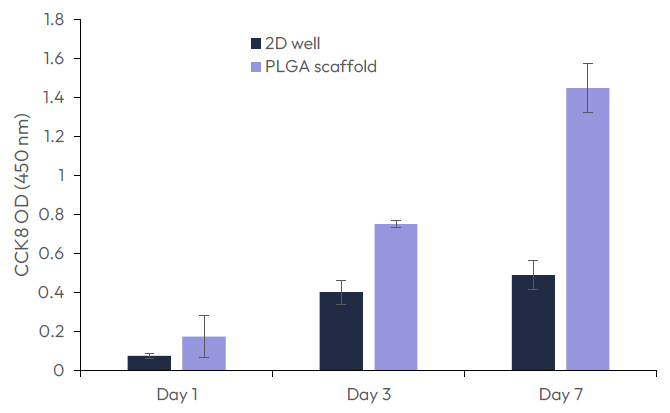

Growth of fibroblast (C2C12) on GelacellTM PLGA scaffolds in comparison with cells on the bottom of the well plate (2D well).

Committed to quality and safety

All Gelacell™ products are manufactured in state-of-the-art ISO Class 7 level cleanrooms, ensuring that the risk of microbial and particulate contamination is minimized. This provides a controlled environment that significantly reduces the number of airborne particles, facilitating the production of high-quality, safe products.

About Gelatex Technologies

Gelatex Technologies, manufacturer of Gelacell™, is a materials technology company specialized in the high-throughput manufacturing of nanofibrous materials using proprietary halospinning technology - the world’s fastest and most cost-effective solution-spinning process. Gelatex, in partnership with Ilex, provides products for 3D cell culture and tissue engineering, and services for customized solutions.

Ilex Life Sciences is an authorized distributor of Gelacell™ products manufactured by Gelatex Technologies.